Below are important tips for ensuring the best possible results when bucking dry flower in our GC and HP buckers.

Home » Dry Bucking Tips

CenturionPro Buckers

Dry Bucking Tips

Dry Bucking Tips

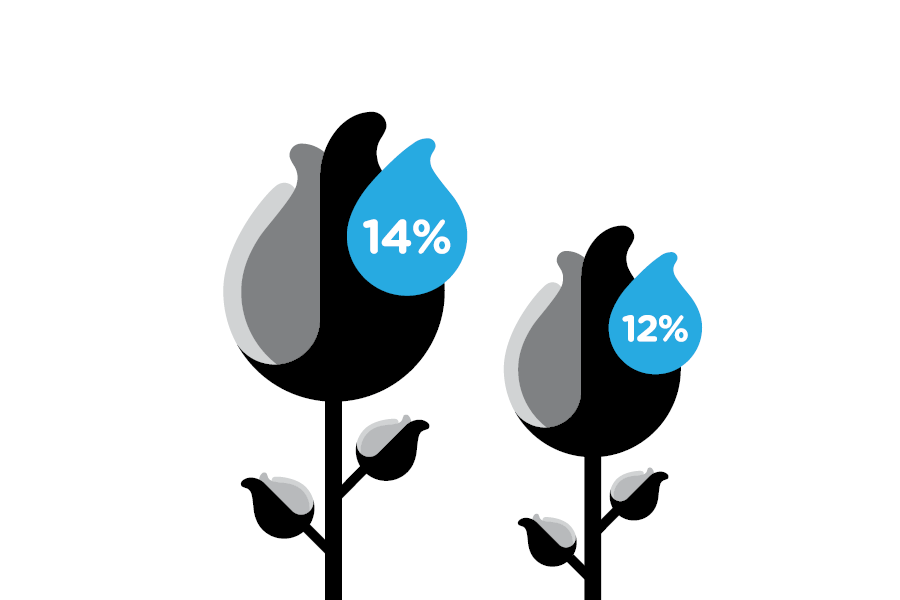

Moisture Content

First and foremost, the moisture content of your cannabis is critical to ensuring minimal damage to the flower. Flower that is too dry will fall apart during the bucking process. Subsequently, if the flower has too much moisture then it will compact and dent.

To achieve the greatest results with dry bucking, moisture content should be between 12 and 14% when using a machine. This can be somewhat hard to measure, but there are a few key indicators that any grower or machine user will be able to feel.

Dry Bucking Tips

Bud Consistency

Buds should be “springy”, as such that when the flower is squeezed between two fingers it will rebound and return to its original shape. If you are bucking by hand, this can be done when the big stems are still pliable and the smaller stems snap when bent. However, when bucking with a machine such as the GC or HP system, the smaller stems must be pliable as well. This ensures that they fold and are stripped upon entering the bucking machine. If too brittle, they will simply break off and will not be properly stripped.

Dry Bucking Tips

Machine Speed

In addition, slowing the machine speed for dry bucking will lead to a better result. Dry bucking at 1/2 or 1/3 of the regular speed will ensure better results. The variable speed control offered by our HP Bucker is a great feature when bucking dry material.

See below for additional environmental, plant and feeding tips to get the most out of your CenturionPro Bucker!